Linear Friction Welding – A High-Speed Movement To Forge Two Pieces Together

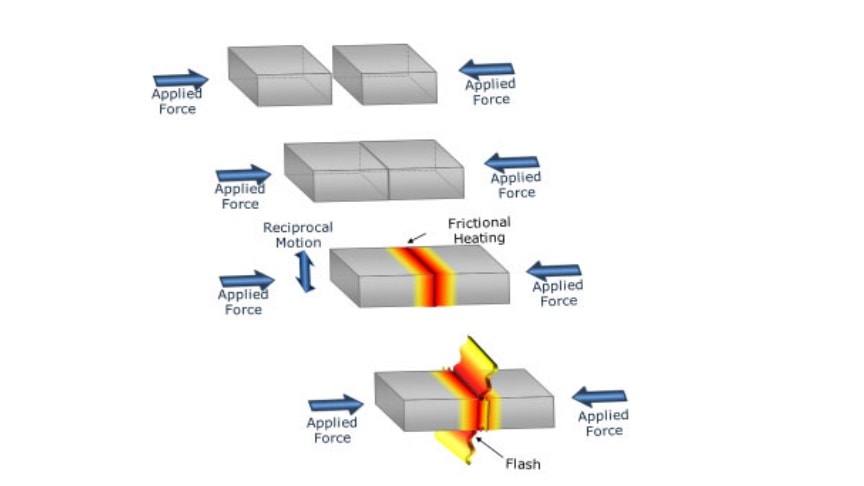

Linear friction welding (LFW) is a solid-state joining process which works by oscillating one workpiece relative to another while under a large, compressive force; see Figure 1 . The friction between the oscillating surfaces produces heat, causing the interface material to plasticise.

The plasticised material is then expelled from the interface causing the workpieces to shorten (burn-off) in the direction of the compressive force.

During the burn-off the interface contaminants, such as oxides and foreign particles, which can affect the properties and possibly the service life of a weld, are expelled into the flash. Once free from contaminants, pure metal to metal contact occurs, resulting in a bond.

Advertisement

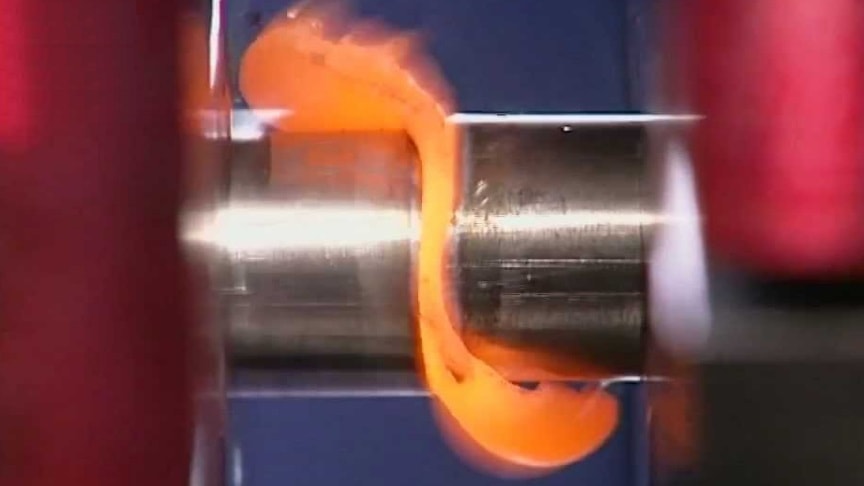

Linear Friction Welding (LFW) is an established niche technology applied by world leading gas turbine aircraft engine manufacturers to fabricate bladed disk (blisk) assemblies. The main challenges are associated with the surface area that can be welded, due to the high forces required, and the control of welding parameters to ensure accuracy of the finished part.

TWI has been involved in projects to manufacture blisks, to use LFW for additive manufacture and in the development of hydraulically actuated machines of varying sizes to serve the growing aerospace market.TWI has been involved with LFW for over 30 years, and it is at the forefront of process development with the research & development community, the machine manufacturers and industrial end users.

https://ift.tt/2UHUIer