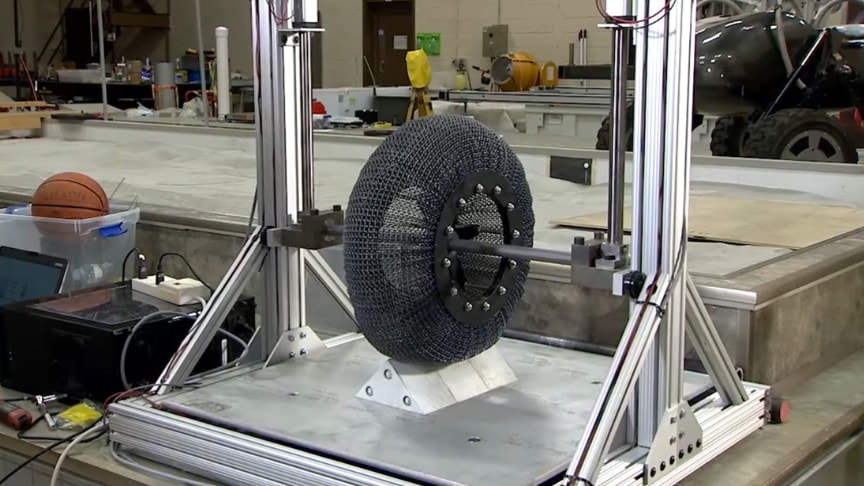

Nasa’s Airless Shape Memory Chainmail Tire – Superelastic Tire

The game changing material that dramatically advanced the development of spring tires was nickel titanium, a shape memory alloy with amazing capabilities as explained by Santo Padula.

source/image: NASA Glenn Research Center

No matter how many rocks it rolls over, this “Superelastic tire” will return to its pre-deformed shape like nothing ever happened. Originally created for future Mars missions, NASA researchers believe that this technology has the potential to someday revolutionize earth tires.

This technology represents the latest evolution of the Spring Tire which was invented by NASA Glenn and Goodyear, and inspired by the Apollo lunar tires.

Advertisement

The novel use of shape memory alloys capable of undergoing high strain as load bearing components, instead of typical elastic materials, results in a tire that can withstand excessive deformation without permanent damage. Using shape memory alloy as radial stiffening elements can also increase the load carrying capacity of the tire.

The Superelastic Tire offers traction equal or superior to conventional pneumatic tires and eliminates both the possibility of puncture failures and running “under-inflated”, thereby improving automobile fuel efficiency and safety. Also, this tire design does not require an inner frame which both simplifies and lightens the tire/wheel assembly.

https://ift.tt/33TcHme