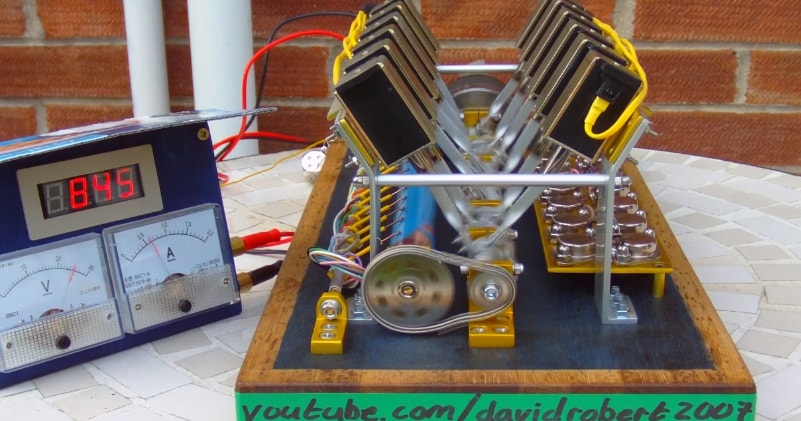

A Home Made V12 Solenoid Engine, Built Using Recycled Materials

A solenoid engine uses the magnetic pull of solenoids to turn a crankshaft, and resembles the architecture of an internal combustion engine./davidrobert2007

source/image: davidrobert2007

The crankshaft on this engine is made up of one hundred and forty individual parts bolted together, and is fully counterweighted to balance the rotational mass.//read more: davidrobert2007

The flywheel is an old drill / lathe chuck of some sort (army surplus), the engine has a tachometer pulse generator on the rear of the timing / distributor shaft to run the red LED tachometer, it uses Meccano timing chain and sprockets, and has a key ignition switch for added style.

Advertisement

This engine can run both as a four stroke or as a two stroke, and can switch while running. This engine does not develop much torque, certainly much less torque than a standard rotary electric motor can produce, for the equivalent power input – for this reason the solenoid engine is just a novelty and an educational model.

Engine description

- Technical details:

- Type: 60 degree V12 electric piston engine

- Maximum RPM: 3,200 RPM

- Input voltage: 24 volts dc

- Speed controller: Mechanical PWM

- Cylinder bore diameter: 8mm

- Piston stroke length: 10mm

- Total theoretical displacement: 6cc

- Firing order: 1, 12, 5, 8, 3, 10, 6, 7, 2, 11, 4, 9 (Same as old type Ferrari)

- Main bearing size: 4x9x4 mm (684zz)

- Big end bearing size: 4x9x4 mm (684zz)

- Flywheel mass: 900g

- Switching transistors: 2N3055

- Solenoid model: SOLEN 121E16530 (with built in flyback diode)

- Total mass of engine: 6kg approximately

- Exhaust emissions: zero//via: davidrobert2007